Why do you need Stone Waster Container?

stone waste container is an essential tool designed for the stone fabrication and construction industries, primarily used for collecting and managing waste and debris generated during processing. It enhances workplace cleanliness, reduces safety hazards, and ensures compliance with environmental standards. With a robust structure, it can withstand the weight and sharp edges of stone, making it suitable for various types of waste. By centralizing waste management, it improves operational efficiency and reduces transportation and disposal costs, making it an indispensable and practical solution for stone processing businesses.

Speedone Slab Lifter & Clamps

Lifter&Clamps Features

- Wide Gripping Range: Compatible with various thicknesses and sizes of slabs, offering flexibility for different specifications.

- Strong Load Capacity: Robust and durable structural design ensures safe lifting of heavy stone slabs.

- Multi-Directional Rotation: Enables precise rotation and movement of slabs during lifting, ideal for complex construction scenarios.

- Efficient Lifting: Works seamlessly with hoisting equipment to achieve quick and efficient lifting operations, significantly improving work productivity.

SPEEDONE‘S Slab Lifters & Clamps

Your reliable assistants for lifting and handling stone materials. From processing to installation, they make stone handling more efficient and safer.

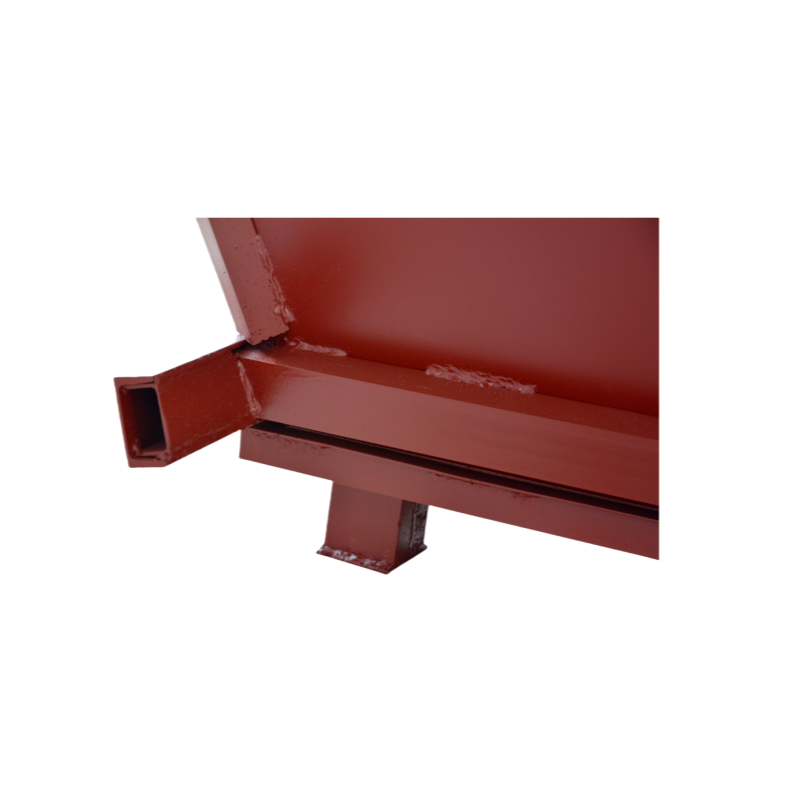

Stone Waster Container

The stone waste container is a vital asset for the stone fabrication and construction industries. It is specifically designed to address the challenges of managing heavy and irregular stone debris generated during cutting, polishing, and processing activities. By centralizing and securely containing waste, the container minimizes workplace hazards, such as tripping risks and equipment damage, caused by scattered debris.

Learn MoreEnhance Your Efficiency

Horizontal

Stone Lifter

Clamp

Double-sided opening waste recycling container for construction materials, with a bottom-opening mechanism for dumping waste. Suitable for use with forklifts or cranes, featuring a 5mm thick steel plate.

Dumpster Bin(Double Sides Iopen)-G

Forklift Stone Waster Container

Side-opening dumpster bin (operated by iron rod), designed for ease of access and waste disposal. It can be used with forklifts or cranes, constructed with 5mm thick steel plates. The bin has a net weight of 300kg and a capacity of 1.6 cubic meters.

Dumpster Bin(Side Open By Iron Rod)

Forklift Stone Waster ContainerAll Products

This is where visitors can browse products in your store.

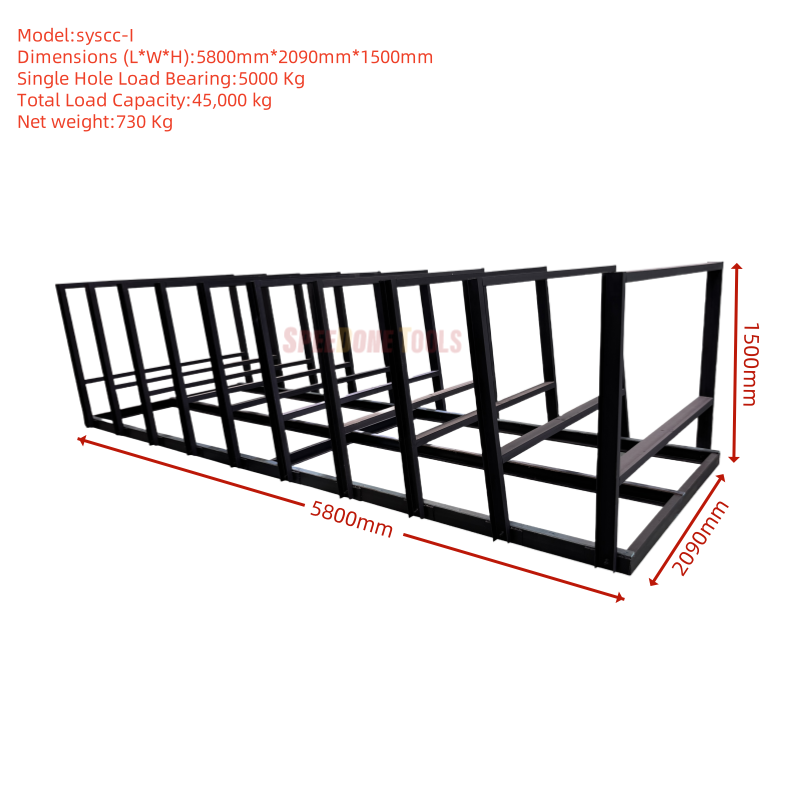

Heavy Duty A-Frame Steel Rack for Industrial Usage Corrosion Protected Truck Storage and Warehouse Display of Granite Slab

Stone Glass Slab Heavy-duty China factory Hot Sale A Frame Storage Transport Rack Trolley

Hot Sale Steel Storage Rack for Line Display Warehouse Rack for Stone Marble Granite Quartz Pallet Racking Carton Packing

Corrosion-Protected Steel A-Frame Storage Rack for Stone Slab for Warehouse Garage Usage Ships to Brazil with Bundle Handler

Contact Us

We would love to speak with you.

Feel free to reach out using the below details.

FAQ

ask us

anything

-

Q:What are your company’s main competitive advantages?

Speedone specializes in the research, development, and customization of stone tool solutions, offering high-quality and reliable stone tool equipment. With our own factory, we work directly with customers, eliminating intermediaries to help reduce procurement costs while ensuring prompt responses and excellent service.

-

Q:What are the production lead time and delivery schedule?

The production lead time for standard products is typically 3–4 weeks. For custom products, the timeline depends on the complexity of the requirements. Delivery details will be specified in the quotation.

-

Q: Can you provide samples or test products?

Yes, we can provide samples for testing based on customer requirements, but specific terms and costs need to be confirmed in advance.

-

Q: Do your transport equipment support usage on various floor surfaces?

Yes, our equipment is equipped with high-performance solid tires, offering strong grip and excellent shock absorption. They are suitable for epoxy-coated floors, concrete surfaces, and other smooth surfaces without causing damage.

-

Q: What is your after-sales service and warranty policy?

We offer a standard one-year warranty, during which customers can enjoy free repairs and technical support. Additionally, we provide lifelong technical consulting services.