Slab Lifters are commonly used in the construction, decoration, and even the stone processing businesses as professional handling tools for varying types of plates. Most importantly, as the scope of projects keep on increasing alongside other varieties of plates, choosing the right Slab Lifter becomes paramount.

Carrying around heavy stones like marbles or granite, or even lighter materials like tiles and artificial stone slabs become efficient and safe with the right Slab Lifter. Not only does it improve work efficiency, it also maximizes the safety of operators.

A reliable Slab Lifter can make handling easier while supporting the business’s project requirements. In the following sections, we will provide you tips on how to select the right slabs and model so that you can make an informed decision.

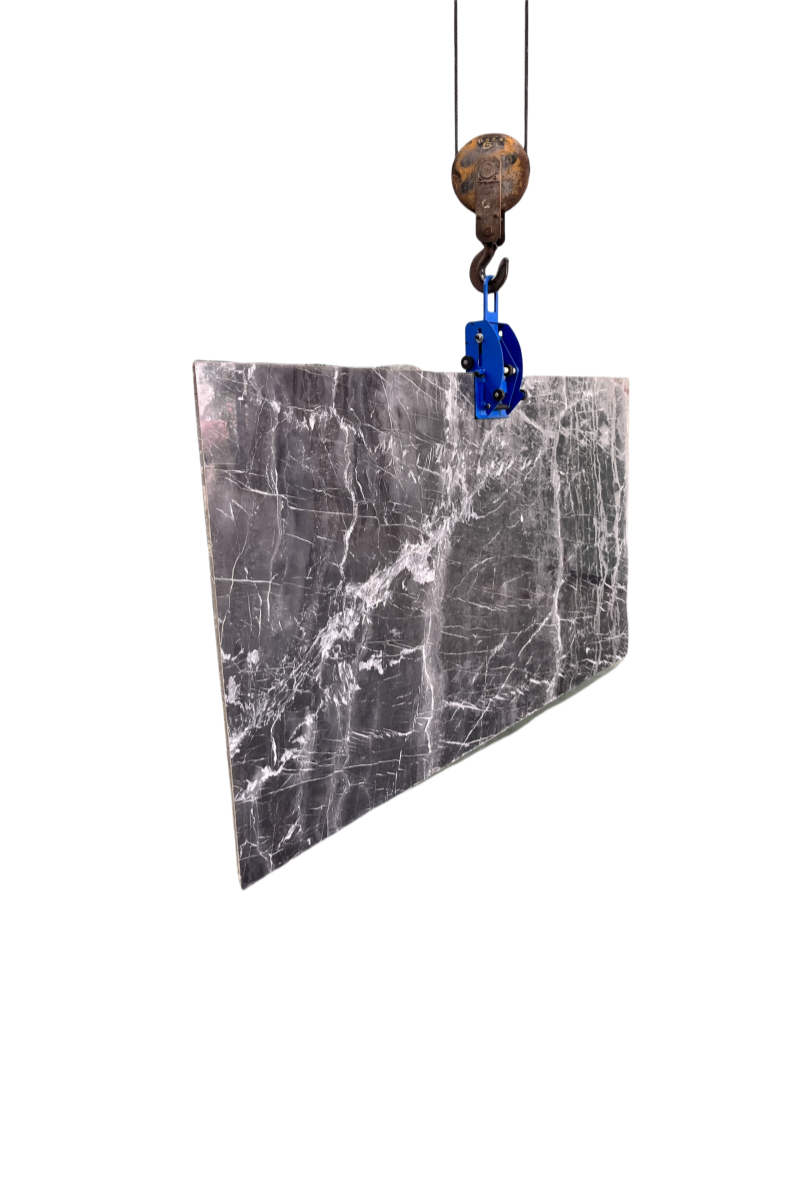

stone slab clamp lifter

What Is A Slab Lifter?

Slab Lifter (plate lifter) is industrial machinery tailor-made for the transportation and elevation of slabs from various industries such as construction, stone processing, logistics, or even glass making. The slab lifters utilize mechanical or vacuum attachments to lift heavy slabs of stone, concrete, or even glass which are placed on the ground or other workbenches to the desired locations. This helps improves work efficiency while lowering labor intensity drastically.

Slab Lifters are designed with safety and stability in mind which is why some models are equipped with anti-slip clamps, multi-point gripping devices or even vacuum suction cups to prevent voids or damages to the plates. Adjusting these Slab Lifters is simple since they can be controlled manually or electronically making the adjustment for various sizes and weight of the slab more simpler. Nowadays, modern slab lifters are equipped with advanced systems such as automatic sensing, remote control and other functions which further increases the efficiency and production of industrial work.

What are the processes of Slab Lifter operation?

Slab lifter is capable of handling heavy objects like tiles and stones. If it is used correctly, not only is the lifting of heavy objects made easier, but it also allows the user to do it safely. Therefore, check all the equipment including the hydraulic or pneumatic clamping systems to ensure everything is in working condition and prepared for usage.

Next, to install the slab onto the lifter clamping device, make sure the piece is adequately secured to avoid slipping off. A loose piece may result in danger during transportation of the slab. To ensure maximum safety, keep the slab horizontal to maintain the balance of the object. After placing it in the designated area, carefully disengage the clamps without moving the slab anymore to avoid damage.

Which slabs are appropriate to use with Slab Lifter?

Slab Lifter is designed for many kinds of slabs, mainly used in construction, stoneworking, and decorative industries. Usual types of slabs are:

Natural stone

Highly dense and heavy stones like granite, marble, and others can be moved around quickly using Slab Lifters thus improving handling productivity and minimizing the amount of work done.

Artificial slabs

Quartz, slabs of artificial marbles and similar types of artificial stone can also be transported and handled using the Slab Lifter. Their surfaces are smooth, and the metal clamping mechanism grasps them without damaging the slabs.

Tiles and Ceramic Panels

Slab Lifter improves the safety and practicality of handling tiles. They can be used for tiles with different thicknesses and sizes while lowering the chances of tiles breaking during use.

Other Building Panels

Slab Lifter can also be used for handling various dense building panels like embossed steel panels, composite panels, and other slike thus improving handling productivity and reducing damage rate.

How much weight can a Slab Lifter carry?

The amount of weight a Slab Lifter can carry is really dependent on the model design. The common market models are usually classified within the following ranges:

Standard Manual Slab Lifter

200 kg and 500 kg load capacity that is suitable for small and medium-sized panels.

Hydraulic or Pneumatic Slab Lifter

These models usually have a higher load capacity than standard models, with some higher-performing models able to lift 1,000 kg or more, which makes them ideal for heavy stone and large panels.

Customized Models

For newer models, Slab Lifters are designed to be adjustable to specific project requirements, where the load capacity can be set to maneuver oversized panels or heavy materials.

But what are the methods to ensuring safety with the slab lift?

Making sure your slab lift is used securely is the most important task for all personnel. To begin with, certain components of this equipment should be examined prior to usage. The pillars of the equipment must be a fully functional. During the process, it is also vital to keep a close eye on the slabs as well as where the center of gravity is to eliminate the chances of tilting or slipping while the machine is in motion.

Furthermore, in order to prevent risks posed by improper usage, operators must receive in-depth training on the proper Handling and Use of the Slab Lifter. When carrying out their responsibilities, employees must choose a Slab Lifter that is appropriate for the dimensions and mass of the slab to avoid any safety concerns related to overuse of the machine.

Lastly, all operators must maintain a relaxed demeanor for on-site transportation and limit abrupt movements, mainly during the lifting and positioning of slabs. Exercising extreme caution by performing tasks slowly mitigates risks.

How does the operator maintain the Slab Lifter?

To enable the Slab Lifter to operate effectively for an extended period of time, it is essential to carry out routine maintenance. Below are the maintenance measures applicable to Slab Lifters:

To avoid wearing of the device, it is best to replace such device before it breaks.

Every time the device stubbornly gags, always check its parts to detect damage or looseness. If damaged, repair or tighten the loose parts immediately.

Use of Slab Lifters is usually driven by hydraulic system. Therefore, it is important to monitor the level and quality of the hydraulic oil because insufficient quantity or poor quality can negatively impact equipment performance.

The equipment must be sanitized.

Cleaning is essential after every utilization of the apparatus. The hydraulic system, clamping device, and air pressure systems should receive thorough clean-up so as to ensure dirt will not affect the normal utilization of the equipment.

Make sure to inspect the lifting system.

It is very important to regularly check for leakage, looseness or wear within the lifting system of the equipment in use. This is important so that lifting the equipment does not become loose and jerky.

slab clamp lifter application

Finding the best slab lifter model and brand for your needs.

The right Slab Lifter will determine the effectiveness of the handling process which is very important. Start by determining the kind and weight of slabs you have to handle and consider these first when selecting a Slab Lifter. A manual Slab Lifter will be able to sufficiently meet the needs of those who only occasionally need to handle lighter slabs. However, those who have to work with large or heavy stones will find that hydraulic or pneumatic models will be more suitable as they provide higher load-bearing capacity which ensures safe and efficient handling.

Also consider how often you will be lifting slabs with the Slab Lifter. If you are going to regularly use a Slab Lifter, you may want to select a more durable one as it will greatly reduce equipment failure and improve work efficiency. In case you are unsure of which model to select, you can consult us with the specifics of your project and we will assist you in choosing the most appropriate model. We have a wide range of Slab Lifters of different specifications suited for various environments and needs.

When selecting a brand, it is critical to pick one that is reputable and has great after-sales services. High-quality brands can ensure product quality and maintenance support, so that your equipment can operate stably for a long time. Our firm manufactures top-quality Slab Lifters and is highly focused on providing the best fit solutions to their customers. Regardless whether it is a big project or daily lifting, our products are guaranteed to increase handling productivity and decrease labor requirements.

Should you need clarification regarding selection of Slab Lifter of please feel free to check our website or call customer service. After understanding your requirements, we will be able to recommend the best model to serve your needs. Choosing our products, you can not only get top-quality equipment, but also unrivalled after-sales services that make you work easier and safer.

Feature Product

-

Stone Glass Slab Heavy-duty China factory Hot S...

Stone Glass Slab Heavy-duty China factory Hot S...Product Introduction: The Stone Glass Slab Heav...

-

New Type Stone Waster Storage Bin Drop Bottom D...

New Type Stone Waster Storage Bin Drop Bottom D...Product Description Overview: The New Type Ston...